Service around the clock and assembly on the spot have made REPA what it is today; a big and well-known supplier of conveyor belts. For a production company that attaches a great deal of value to service, these two strengths are extremely important. In combination of course, with a great assortment of conveyor belts of top quality at competitive prices. Everybody knows that a stagnating production line is very costly. Belt malfunctions are always inconvenient; try to find a service crew in the weekend or in the middle of the night. REPA’s team includes more than 32 allround service technicians who are all specifically trained to get the end customer up and running again as quickly as possible so that the damage remains limited. However, avoiding calamities and malfunctions altogether is of course the most effective approach! That is why REPA also works with maintenance contracts. For example, when customers have a maintenance contract, REPA regularly performs inspections. In this way, any problem issues can be mapped out in advance. It goes without saying that such a strategy prevents most malfunctions.

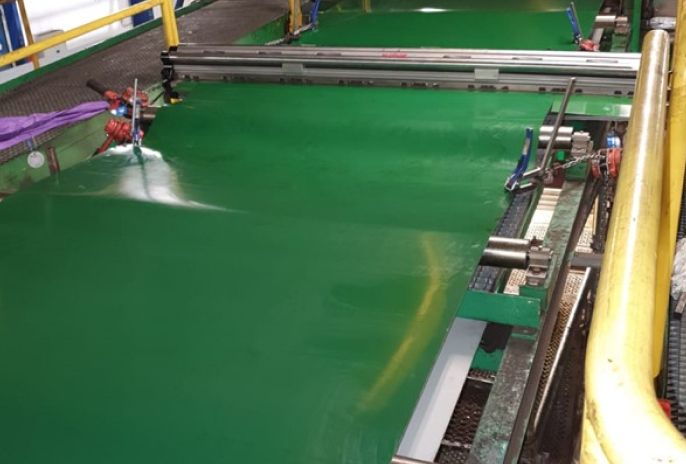

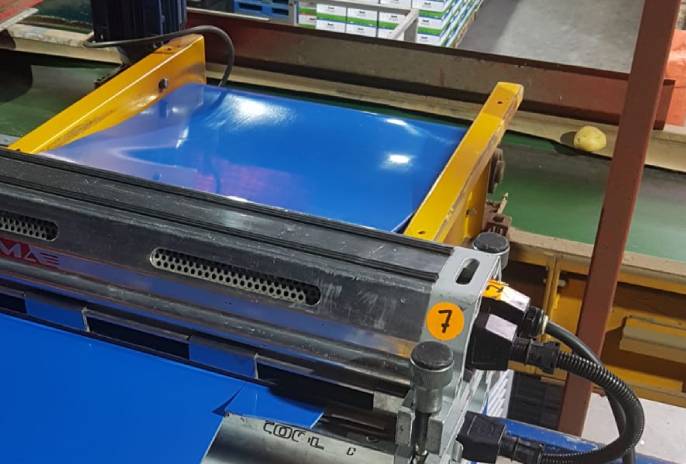

With our newest air-cooled presses developed at Beltquip, we are able to vulcanise belts at the spot up to a bandwidth of 5000 mm.

In addition, we can vulcanise rubber conveyor belts both at a hot (provided that there is sufficient space) and a cold temperature. The advantage of hot vulcanisation is that after this procedure, the belt is immediately ready to go into production again. In case of cold vulcanisation, it takes on average 4 to 5 hours for the weld to dry (depending on the circumstances). Also, we can make your belts endless by means of a mechanical connector.

Finally, our programme includes activities such as covering large drums and dump points and installing scrapers and steering rollers.