Curve conveyors with roller bearings

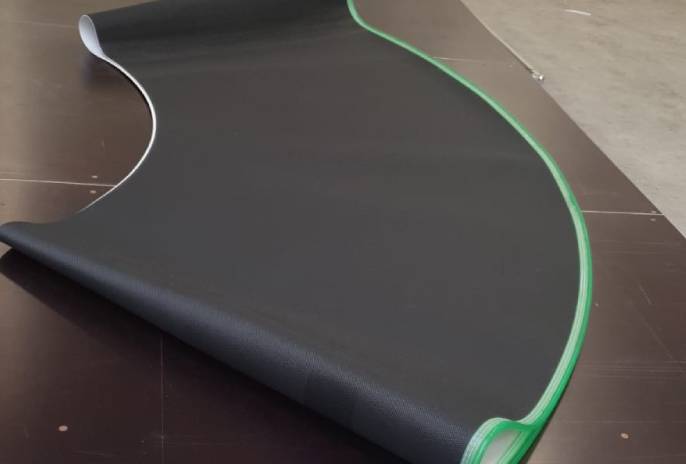

Curve conveyor with side edge

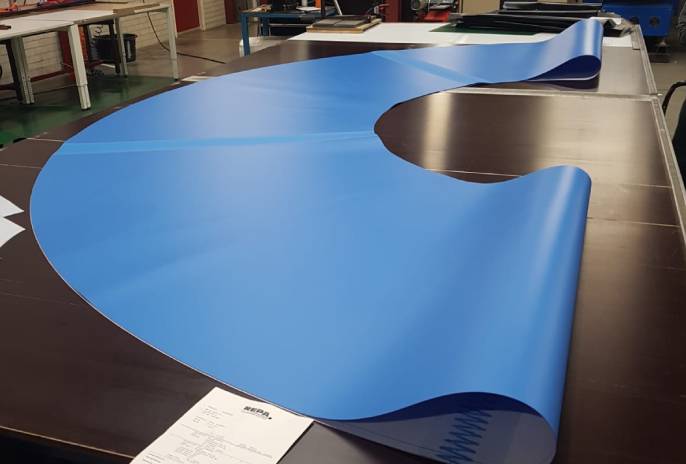

Curve conveyor PU blue for the food industry

Curve conveyors are frequently used in distribution centres and at airports, but also by bakeries and other food processing businesses. REPA manufactures these belts in-house in PVC and PU. In various colours and profiles of course, depending upon the type of product that has to be transported and the environmental conditions.

There are different types of curve conveyors: with roller bearings, chains, and side edges. Bakeries sometimes use curve conveyors equipped with elastic bands. But the larger OEM-companies virtually always work with curve conveyors that include side passages. They come in various types and sizes, of which REPA has about 150 ready in stock. This means that our service-staff can deliver and assemble the belts directly on a 24/7 basis. So in case of malfunction, the delay will be reduced to a minimum. To avoid calamities, REPA also runs inspections at the client’s premises. For keeping the curve conveyor in good condition, it is essential that the roller bearings are adjusted correctly. And also the tension levels within the belt and on the bearings are important factors that have an influence on the conveyor’s lifespan. All members of our maintenance crew are trained to see to it that these issues are perfectly taken care of.