The agricultural sector requires a large variety of conveyor belt applications. REPA can meet this extensive demand and usually has its products available from stock. Of course, all belts can be equipped with additional elements, such as cleats (full pvc or fabric-enforced), sidewalls, tracking guides, and anti-spill edges. REPA’s belts run very smoothly and are highly wear-and-tear resistant.

REPA has a complete range of products for distribution centres.

In order to reduce noise to a minimum, the belts are all made of noise-resistant fabric. Their width stability is generally high, which means that they are very easy to steer, also in case of lateral load. For optimum noise reduction, all belts contain whisper fabrics. The width stability level of the belts is generally high, also in case of lateral load.

For transporting the products, REPA has various high-adhesion profile belts in stock to prevent the items from sliding back.

In collaboration with our technical engineers, the belts can also be designed tailor-made specifically according to our clients’ wishes.

In the food industry, the requirements are becoming stricter all the time. This trend plays an important role in the production process, and also has an impact on the manufacturing of the belts. REPA has more than 25 years of experience in the food branch and accordingly offers an extensive assortment of conveyor belts. For the bakery industry, we have excellent PU-belts with knife edges, manufactured on a calendar. We have these belts in stock in the colours blue and white. We also offer belts for the transportation of meat, fish, poultry, vegetables, and fruit.

There are various special requirements for conveyor systems used at airports, for example flame-retardancy. In addition, REPA has developed an energy-efficient fabric. Tests in the field as well as comparisons of several applications have shown an average reduction of 45%. So, a lot of money can be saved here. For more information, please contact our technical staff. They can advise you whether this fabric would suit your installation.

Apart from its very complete rubber conveyor belt assortment, REPA has developed a number of plastic belt types that have proven to perform very well in – for example – the metalworking industry, the waste sector, and the recycling branch.

These belts are oil-, grease-, and wear-and-tear-resistant and have excellent loading properties! They are produced up to a band width of 3200 mm and are available in stock.

REPA has various belts for the metalworking industry in its assortment. All these belts have wear-resistant topcoats, both in rubber and in PU. The steering properties of the belts are excellent, which is ideal for lateral loads.

For wrapping systems, we can also vulcanise special felt belts on the spot. In this way, these machines do not need to be disassembled, which saves a lot of time, and thus money.

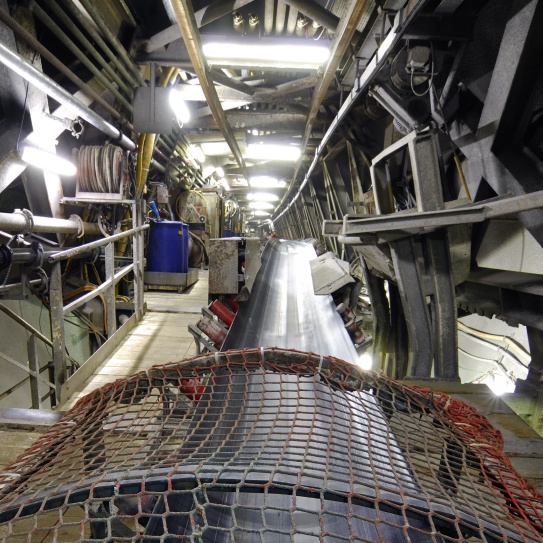

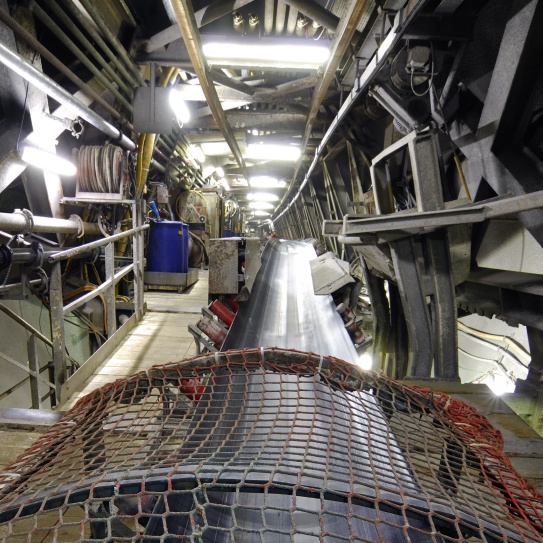

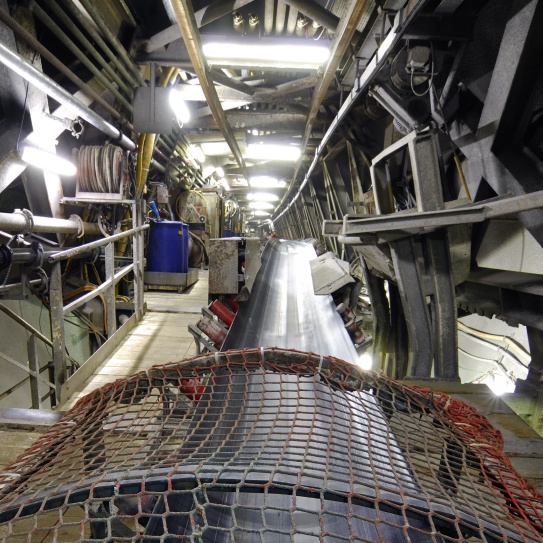

We also have more than 60 different types of heavy-duty black rubber belts in stock, suitable for the mining industry. We offer a variety of coating thicknesses and are able to adjust the belts for obtaining the desired degree of wear-and-tear-, impact-, oil-, or/and temperature-resistance, as well as flame-retardancy. In addition, we can deliver several types of steel wire belts.

REPA has developed various belts that are resistant to chemical substances, oil, fat, cuts, and wear-and-tear. These characteristics are specifically required in the recycling and waste processing industry. Furthermore, in collaboration with the client and our engineers, we can also produce tailor-made belts.

The operating conditions for conveyor belts used in the sand and gravel/cement industry can be fairly abrasive. Apart from the quick wear-and-tear caused by the products, factors such as temperature can play a role. An example is glowing hot tiles straight from the oven. For the transportation of these tiles, REPA has designed rubber belts that can resist peaks of 400 degrees. In addition, we developed a plastic belt with a thick PU-coated layer that can also accommodate tiles, and that has excellent steering properties. Ideal in combination with our self-steering rollers.